Valve Parts (Body, Bonnet, Trim)

VALVE PARTS

BODY

The body is a key element: it contains the moving components in contact with the fluid and has to withstand the pressure existing in the piping system.

The body can be manufactured by cast or forge in a variety of shapes, designs and material grades.

In the oil and gas industry, the most common material for cast bodies is ASTM A 216 and ASTM A 105 for forged bodies (high-temperature service). For low-temperature service, ASTM A352 LCB/LCB and ASTM A350 LF2/LF3 are used, respectively, for cast and forged bodies.

As the temperature, the pressure or the corrosion increase, stainless steel bodies become necessary: ASTM A351 CF8 (SS304) and CF8M (SS316) for cast devices, and the various ASTM A182 Fxx (F304, F316, F321, F347) for forged types.

For specific applications, special material grades with even stronger corrosion resistance are used, such as super austenitic stainless steels (SMO 254), duplex and super duplex steels (F44, F51, F53, F55), and nickel alloys (Inconel, Incoloy, Hastelloy).

For marine applications, non-ferrous materials or alloys the elective choice, like Monel, Cupronickel, Aluminum-bronze alloys and other alloys combining Nickel, Copper, Aluminium. Cast iron bodies, which are the cheapest types, are used for water distribution (low-pressure applications).

BODY END CONNECTIONS

Valves can be connected to other mechanical devices and pipes in different ways. The main end types are flanged and buttweld (for devices above 2 inches) and socket weld or threaded/screwed (NPT or BSP) for small diameter devices. The butterfly has more articulated end types, like lug, wafer, and double flanged ends.

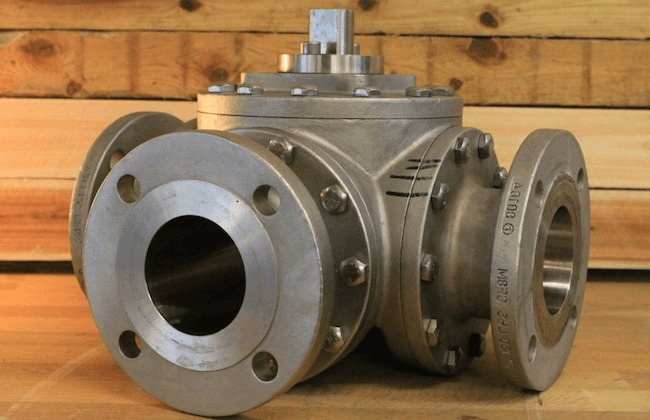

FLANGED ENDS

In this case, the device has two flanged ends that can be connected with a pipe by using a mating (companion) flange.

A flanged connection requires a proper stud bolt and nut, as indicated by the ASME B16.5 specification, and a suitable gasket.

Flanged connections are common for larger diameter valves, and they ensure long-lasting, and strong, joints.

The flange face may be raised, flat, ring joint, tongue and groove and male & female (the most common finish is the RF type, i.e. raised face), and be finished in any of the available variants (stock, serrated or smooth).

SOCKET WELD and BUTTWELD ENDS

Socket weld (left) vs butt weld end type (right)

Valves with socket weld ASME B16.11 or buttweld ends ASME B16.25 are welded with the connecting pipe.

Welded connections are more expensive to execute than flanged joints, as they require more work, but are more reliable and less prone to leakages in the long run.

Socket weld and buttweld ends are used for high-pressure pipelines (socket weld for smaller sizes, below 2 inches, and buttweld for larger diameters).

Butwel connections require full welding of the beveled ends of the two parts to be joined, whereas socket weld connections are made by fillet welds.

THREADED END CONNECTION

In this case, the device is connected to the pipe by a thread (tapered thread), which may be BSP or NPT (more common in the petrochemical industry).

This type of connection is used for low-pressure pipelines with bore size below 2 inches, not subject to mechanical forces as vibration and elongation.

Threaded connections are quicker to execute and cheaper, as the pipe is simply screwed onto the valve, without the need for flanges, stud bolts or welding operations.

In case of leakage, however, threaded connections need to be changed and can’t be repaired (which is instead possible for the two previous types of pipe to end connections).

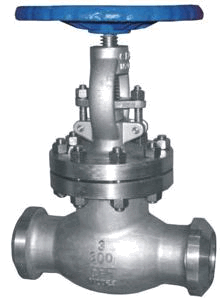

BONNET

Bonnets are other important components for the gate and globe type. By dismantling the bonnet, the maintenance staff has access to the internal mechanisms and can replace components like the seat, the stem, etc (trim).

Valve bonnets are available in many designs and models (the most typical are: bolted, round bolted, welded, pressure seal) and are manufactured in cast steel or forged steel (generally using the same material grade of the body). The bonnet is connected with the body by a threaded, bolted, or welded joint connections – and different types of gaskets are used to ensure leak-free connections between the body and the bonnet.

Manufacturers strive to optimize the design of this part (to reduce the overall dimension of the device and to ensure that the connection is tight and leakage-proof).

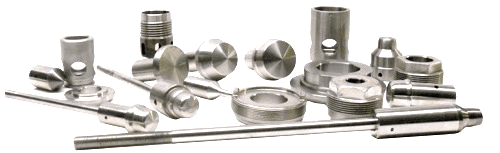

TRIM

The trim is a collective name for all the internal parts of the valve that can be removed and replaced (these parts are also called “wet”, as they are in direct contact with the conveyed fluid).

Typically, the trim includes components as the disc, the seat, the stem, the glands, the bushings and the sleeves needed to guide the stem (the actual list of components that make up the trim depends, actually, by the type of device).

The trim is a fundamental component and materials shall be chosen with care. The factors to consider are pressure, temperature, type of fluid. Typical trim combinations for gate, globe and check valves have been standardized by the API trip chart.

DISC

The disc opens, closes or modulate the flow of the fluid. In the case of a gate valve, the gate (wedge) is the disc of the valve (whereas the disc is called “ball” for ball valves).

The disc opens, closes or modulate the flow of the fluid. In the case of a gate valve, the gate (wedge) is the disc of the valve (whereas the disc is called “ball” for ball valves).

After the body and the bonnet, the disc is the third most important element for the proper performance of a valve. Discs are generally manufactured in forged steel and are often reinforced (hard faced) to enhance the mechanical properties of the base material.

SEATS

Seats accommodate the movements of the disc. Globe or a swing-check valve are fitted with one seat that, in combination with the action of the disc, can open and close the passageway of the fluid and therefore shut-off and/or throttle the fluid.

Gate valves have generally two seats, one on the upper side and the other on the lower side. Seats are often hard-faced. A proper finish of the seats ensures a good seal when the device is in the closed position.

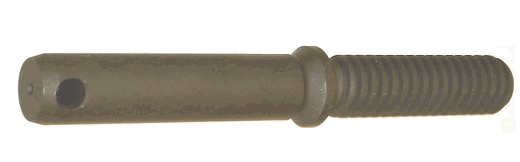

STEM

The stem of a valve is used to open/close and the fluid as it moves the disc. The stem is linked to the valve actuator or to the manual handwheel (or lever), at one end, and is connected to the valve disc on the other end.

The stem of a valve is used to open/close and the fluid as it moves the disc. The stem is linked to the valve actuator or to the manual handwheel (or lever), at one end, and is connected to the valve disc on the other end.

For the gate and globe types, the stem operates a linear motion on the disc, whereas, for a ball, butterfly and plug types, the disc rotates to open or close the device (“quarter turn valves”).

Stems are made of forged steel and are connected to the disc by threading or other means. A proper finish of the stem surface is necessary to prevent leakages.

There are five main types of stems:

- Rotary: This is a standard type of the ball, plug, and butterfly valves. A quarter-turn motion of the stem is needed to open/close the device

- Sliding: In this case, the stem does not execute any rotation. The stem slides in and out the valve to open or close it. This design is common in hand-operated lever rapid opening valves. It is also used in control valves are operated by hydraulic or pneumatic cylinders.

- Rising type with outside screw and yoke (“OS&Y”): the external side of the stem is threaded while the part of the stem which is inside the valve is plain. The threads of the stem are isolated from the medium by the packing. Two alternative designs are available. The “OS&Y” design is common for valves above 2″.

- Rising type with an inside screw (“IS&Y”): The threaded part of the stem is positioned inside the valve body, whereas the stem packing lays outside. With this design, the stem threads are in touch with the medium flowing through the pipeline. Once rotated, the stem and the hand wheel rise together and open the valve.

- Non-rising stem type with inside screw: The threaded part of the stem is inside the valve and does not rise. The valve disc floats on the stem, like a nut if the stem is rotated. Stem threads are in contact with the media of the pipeline, and as such, may be exposed to its corrosive impact. This is the reason why such design is used when the available space to position the valve is too narrow to permit linear movement, and the media does not cause erosion, corrosion or abrasion of the stem material.

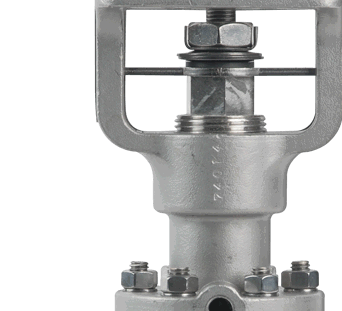

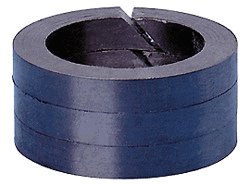

PACKING

The gasket that seals the stem with the bonnet is called packing, and comprises the following components:

- Gland follower, which is a sleeve that compresses the packing, by a gland into the stuffing box.

- Gland, a type of bushing, which compresses the packing into the stuffing box.

- Stuffing box, a chamber in which the packing gets compressed.

- Packing, available in different materials, like PTFE, elastomers, fibrous material, etc.

- A backseat is seating inside the bonnet. The back seat provides a seal between the stem and bonnet and prevents system pressure from building against the valve packing once the valve is fully open. Back seats are often used in gate and globe valves.

- The valve packaging shall be properly designed and manufactured to minimize the possible damages to the stem and minimize the risk of leakages of fluids. On the other hand, it is necessary to observe that a too tight packing may affect the stem.

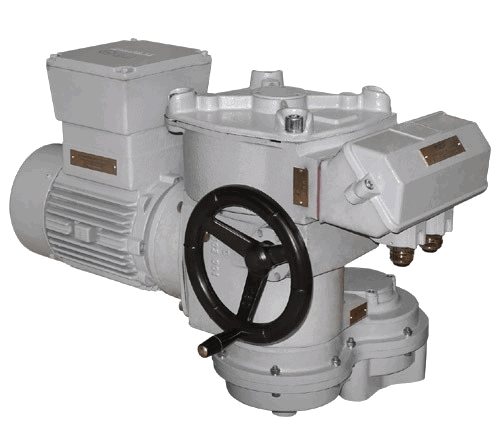

ACTUATOR

A hand operated or manual valve is generally equipped with a hand wheel that can be rotated clockwise or counter-clockwise to open and/or close the valve (typical for gate and globe valves). Ball, plug or butterfly are actuated using a lever (manual quarter turn valves).In the following cases, it is not either possible nor advisable to use manual valves:

- Large dimension valves that operate at high pressures

- Valves that need to be controlled from a remote location

- Valves that require, for the nature of the process, a very fast open or close operation

In all these cases, a valve actuator is needed. The actuator produces linear and rotary motion able to open or close a valve (the actual movement depends of course on the type of the valve, linear or quarter turn). The main types of valves actuators are:

- Gear Actuators

- Electric actuators

- Pneumatic actuators (pneumatic control valves use this type frequently)

- Hydraulic actuators

- Gas over oil actuators

- Solenoid Actuators

Rotork and Auma actuators have the largest market shares within the petrochemical industry.