Globe Valves

Globe valves are used to regulate the flow of a fluid and to shut-off the fluid (even if for shut-off operations ball valves and gate valves shall always be preferred). Globe valves are bi-directional valves, differently from check valves, meaning that the fluid can flow either way within the valve.

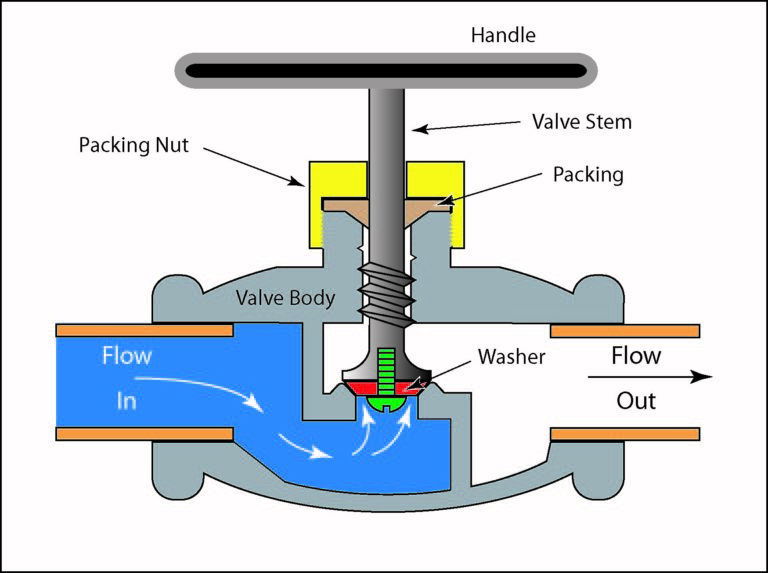

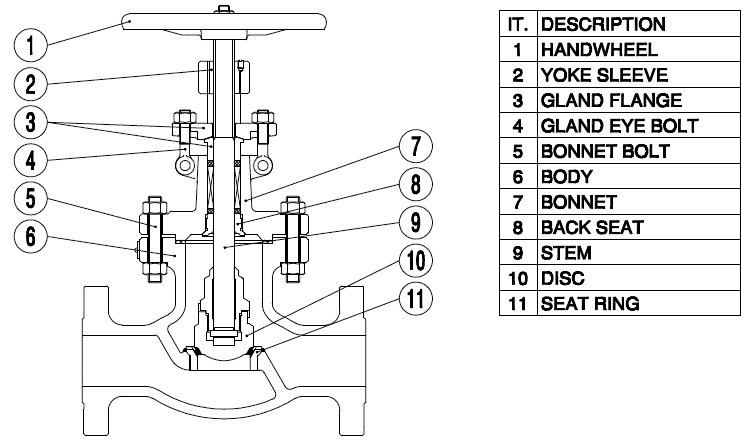

The image illustrates how the valve works and its main components: basically, the flow is managed via a disc that can be lifted (manually or via actuators) from the seat, thus regulating the volume of the allowed flow.

The key specifications for globe valves used for piping applications in the petrochemical industry are:

- BS 1873: cast steel valves

- API 603: stainless steel valves

- API 602/BS 5352: forged steel valves

- API 598 and BS EN 12266-1: valves testing

- ASME B16.10: face to face dimensions for valves

- ASME B16.5 and ASME B16.47: flanged connections

- ASME B16.25: butt weld connections design

- ASME B16.34: pressure and temperature ratings by material grade

GLOBE VALVE ADVANTAGES AND DISADVANTAGES.

The advantages are:

- Good throttling and shut-off capabilities

- Easy to maintain and resurface the seats

- Can be used as a stop-check valve in case the disc is not attached to the stem

The main disadvantages are:

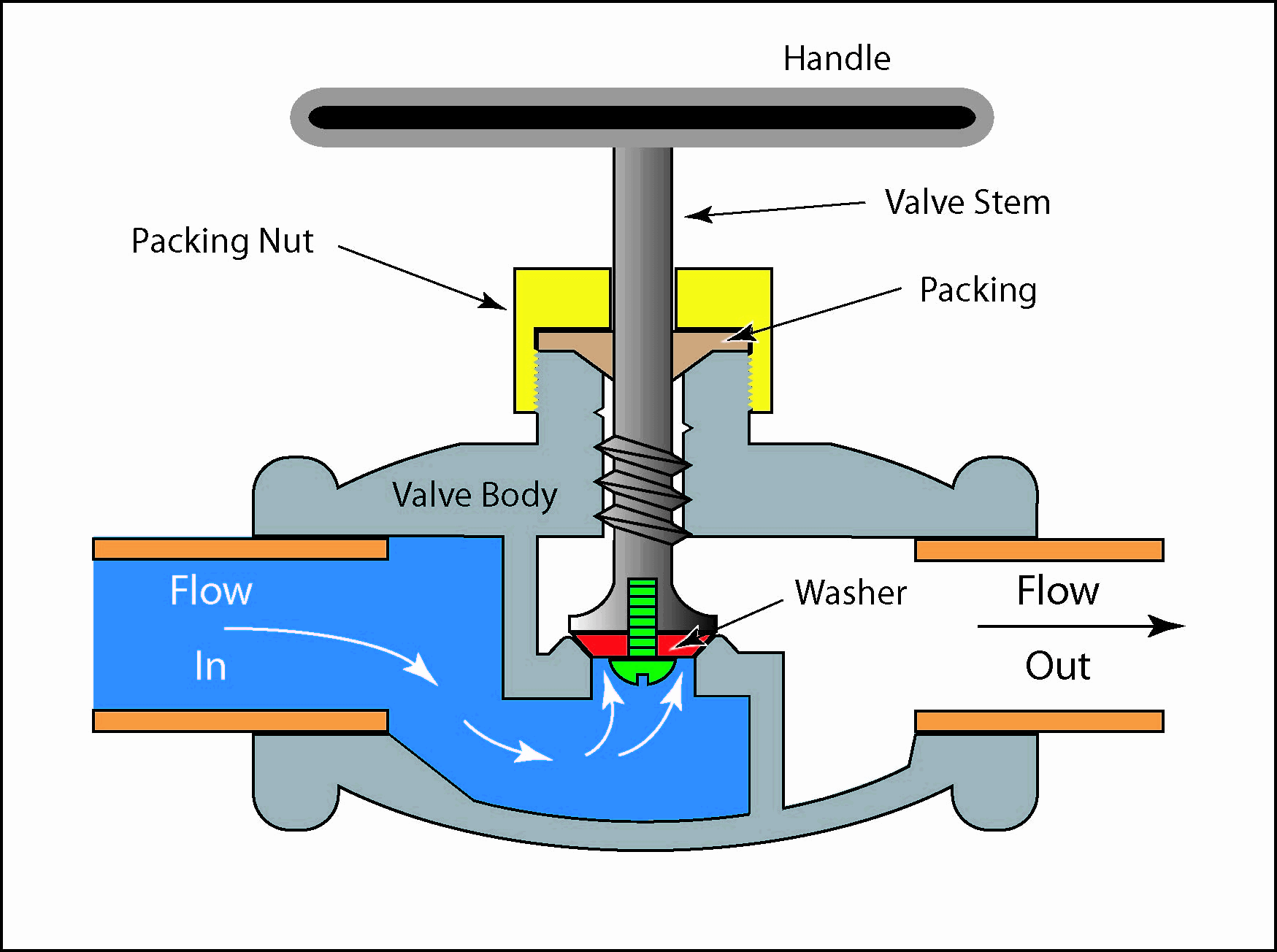

- the valve creates a pressure drop in the piping system (different from gate valves): this is due to the fact that the flow of the fluid is not linear inside the valve, which has an “S-shaped” passageway (see the image below)

- shut-off requires more torque than gate valves

GLOBE VALVE TYPES

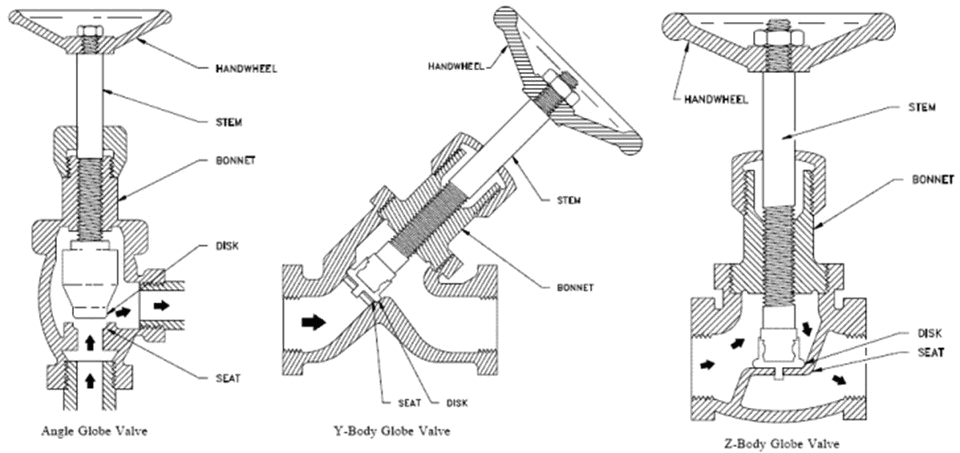

The valve is available in three main types, considering the shape of the body:

- straight or “T” type

- angle or “90 degrees”

- Y pattern or “wye globe valve”

The globe valve symbol in P&ID diagrams is the following: ![]()

GLOBE VALVE VS BALL VALVE

The key difference between a globe and a ball valve is that a ball valve is designed, mainly, for shut-off operations, whereas a globe valve is designed, mainly, to throttle fluids. These two valves are industry-standards respectively for shut-off (ball valve) and for regulation (globe valve) applications.

A globe valve does not fit shut-off operations, due to the pressure drop it creates in the piping system (a problem that does not exist for full bore ball valves).

Ball valves have a long service life even in case of continuous on-off operations; globe valves would deteriorate easily under this type of service.

GLOBE VALVE VS GATE VALVE

The main differences between these two valves are:

- fluid shut off is the main goal of gate valves, whereas flow throttling is the main goal of globe valves

- gate valves have poor, to none, fluid regulation capacity

- gate valves do not generate a pressure drop in the pipeline, globe valves do

- globe valves open faster than gate valves

Concluding on this topic: use a ball valve (or a gate valve) for shut-off operations; use a globe valve for regulation. Do not consider these valves as interchangeable.

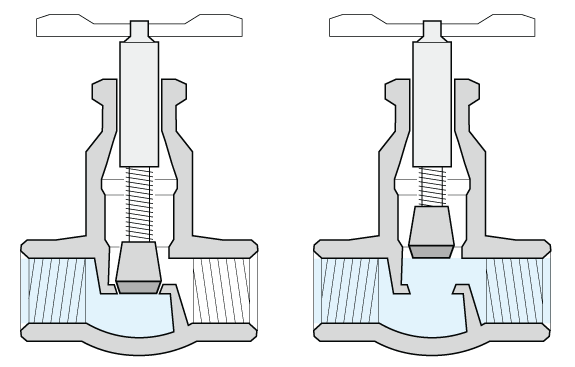

GLOBE VALVE DIAGRAM

A general assembly drawing for globe valves is shown in the image:

Nonetheless, a large number of variations exist, depending on the following factors:

- body material: cast (BS 1873) and forged (API 602/BS 5352)

- bonnet design: standard or pressure seal type (for high-pressure applications)

- bonnet to body connection: bolted or welded

- valve end connections type: flanged (as shown in the image), buttweld, socket weld/threaded (forged bodies)

- disc type

- stem type (rising/non-rising)

- seal type: conical or flat

- specification: BS, API, EN

- type of actuation: manual, with a gearbox, with an actuator

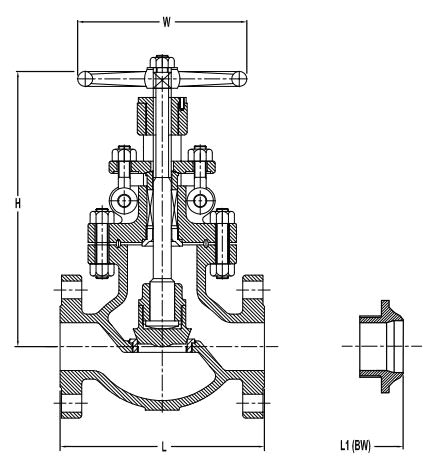

GLOBE VALVES DIMENSIONS

The tables show the dimensions and weights of BS 1873 valves, bolted bonnet type.

CLASS 150

Dimensions in inches (millimeters)

| GEAR OPERATOR RECOMMENDED FOR SIZE 10″ AND ABOVE | |||

|---|---|---|---|

| Sizes | L / L1 | H (Open) | W |

| 2″ | 8 (203) | 13-3/8 (340) | 8-7/8 (225) |

| 2-1/2″ | 8-1/2 (216) | 14-1/2 (368) | 8-7/8 (225) |

| 3″ | 9-1/2 (241) | 16-1/2 (419) | 11-7/8 (302) |

| 4″ | 11-1/2 (292) | 17-3/8 (441) | 12-3/4 (325) |

| 5″ | 14 (356) | 24 (610) | 12-3/4 (325) |

| 6″ | 16 (406) | 24 (610) | 17-3/4 (451) |

| 8″ | 19-1/2 (495) | 26-3/4 (679) | 21-5/8 (549) |

| 10″ | 24-1/2 (622) | 30 (762) | 30 (762) |

| 12″ | 27-1/2 (699) | 33-7/8 (860) | 30 (762) |

| 14″ | 31 (787) | 56 (1422) | 31-1/2 (800) |

| 16″ | 36 (914) | 64 (1626) | 35-1/2 (902) |

CLASS 300

Dimensions in inches (millimeters)

| GEAR OPERATOR RECOMMENDED FOR SIZE 8″ AND ABOVE | |||

|---|---|---|---|

| Sizes | L / L1 | H (Open) | W |

| 2″ | 10-1/2 (267) | 13-3/8 (340) | 9 (229) |

| 2-1/2″ | 11-1/2 (292) | 15-3/8 (390) | 9 (229) |

| 3″ | 12-1/2 (318) | 16-1/2 (419) | 13 (330) |

| 4″ | 14 (356) | 19-3/8 (492) | 14 (356) |

| 5″ | 15-3/4 (400) | 21-1/2 (546) | 15-3/4 (400) |

| 6″ | 17-1/2 (445) | 24-3/8 (619) | 17-3/4 (451) |

| 8″ | 22 (559) | 31-1/4 (794) | 22 (559) |

| 10″ | 24-1/2 (622) | 45 (1143) | 34 (864) |

| 12″ | 28 (711) | 49 (1245) | 34 (864) |

CLASS 600

Dimensions in inches (millimeters)

| GEAR OPERATOR RECOMMENDED FOR SIZE 8″ AND ABOVE | |||

|---|---|---|---|

| Sizes | L / L1 | H (Open) | W |

| 2″ | 11-1/2 (292) | 15-1/2 (394) | 9-1/2 (241) |

| 2-1/2″ | 13 (330) | 17 (432) | 11 (279) |

| 3″ | 14 (356) | 19 (483) | 13 (330) |

| 4″ | 17 (432) | 21 (533) | 14 (356) |

| 5″ | 20 (508) | 25 (635) | 15-3/4 (400) |

| 6″ | 22 (559) | 26-7/8 (683) | 18 (457) |

| 8″ | 26 (660) | 35 (889) | 20 (508) |

| 10″ | 31 (787) | 49 (1245) | 24 (610) |

| 12″ | 33 (838) | 58 (1473) | 30 (762) |

CLASS 900

Dimensions in inches (millimeters)

| GEAR OPERATOR RECOMMENDED FOR SIZE 6″ AND ABOVE | |||

|---|---|---|---|

| Sizes | L / L1 | H (Open) | W |

| 2″ | 14-1/2 (368) | 20-1/2 (521) | 12 (305) |

| 3″ | 15 (381) | 22-3/4 (578) | 14 (356) |

| 4″ | 18 (457) | 26-1/2 (673) | 21-1/2 (546) |

| 6″ | 24 (610) | 36 (914) | 20 (508) |

| 8″ | 29 (737) | 37 (940) | 24 (610) |

GLOBE VALVE DIMENSION CLASS 1500

Dimensions in inches (millimeters)

| GEAR OPERATOR RECOMMENDED FOR SIZE 6″ AND ABOVE | |||

|---|---|---|---|

| Sizes | L / L1 | H (Open) | W |

| 2″ | 14-1/2 (368) | 24 (610) | 14 (356) |

| 3″ | 18-1/2 (470) | 26 (660) | 16 (406) |

| 4″ | 21-1/2 (546) | 28 (711) | 18 (457) |

| 6″ | 27-3/4 (705) | 37-1/2 (952) | 24 (610) |

| 8″ | 32-3/4 (832) | 45 (1143) | 24 (610) |

GLOBE VALVE DIMENSION CLASS 2500

Dimensions in inches (millimeters)

| GEAR OPERATOR RECOMMENDED FOR SIZE 6″ AND ABOVE | |||

|---|---|---|---|

| Sizes | L / L1 | H (Open) | W |

| 2″ | 17-3/4 (451) | 25-1/2 (648) | 16 (406) |

| 3″ | 22-3/4 (578) | 32-1/2 (825) | 20 (508) |

| 4″ | 26-1/2 (673) | 47 (1194) | 24 (610) |

| 6″ | 36 (914) | 70-1/2 (1790) | 28 (711) |

| 8″ | 40-1/4 (1022) | / | / |